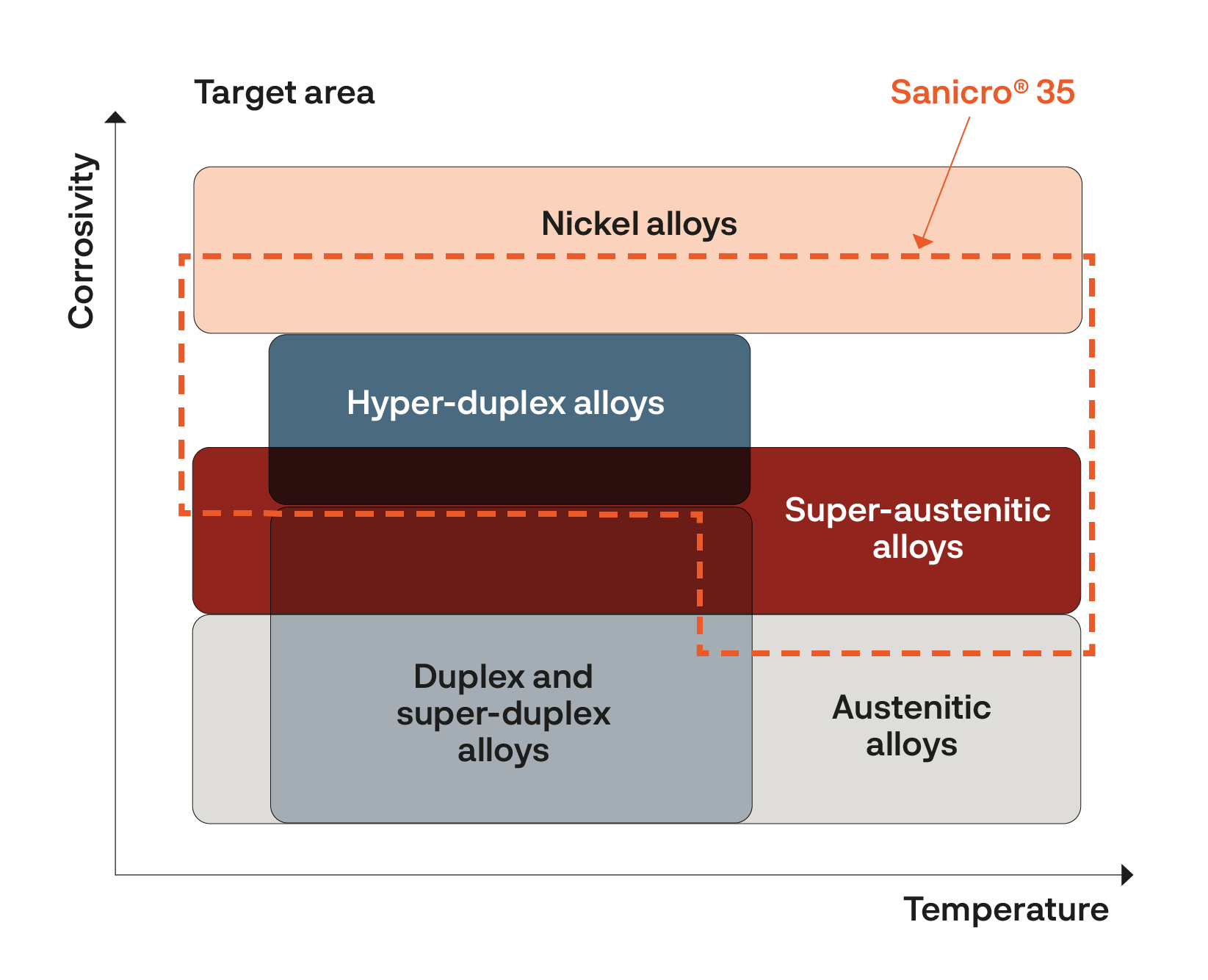

Instead of investing in costly nickel alloys for your heat exchanger tubing, why not choose a cost-efficient alternative? This is why leading producers with demanding process applications are increasingly opting for Sanicro® 35 to bridge the gap between standard duplex or austenitic grades and traditional nickel alloys.

メニュー

- Home

-

Products

-

Wire

- Ultra-fine medical wire

- Fine wire

- Electroplating and electropolishing of wire and parts

-

Tube, pipe, fittings and flanges

- Advancing American Industry through materials technology

- Articles

- E-Track

-

Tradeshows

- Subsea Tieback

- AMPP Annual Conference + Expo 2025

- OMC MED Energy Conference & Exhibition

- Canadian Hydrogen Convention 2025

- Hydrogen Technology Expo 2025

- SMR & Advanced Reactor 2025

- OMTEC Conference 2025

- Carbon Capture Technology Expo North America 2025

- OTC Asia 2024

- AMPP Annual Conference + Expo

- Canadian Hydrogen Convention

- OMTEC Conference

- AMPP Italy Conference and Expo 2024

- Hydrogen Technology Expo North America 2024

- Farnborough International Airshow

- NAICE 2024

- LARTC 2024

- Rio Oil and Gas 2024

- Heat Exchanger World Americas 2024

- ADIPEC 2024

- Duplex World and Heat Exchanger World 2024

- CORCON 2024

- India Energy Week 2025

- Oil Gas & Power World Expo 2025

- Technical services

- Approvals and standards

- Stock program

-

Tubular products

- Zirconium tubes

- Umbilical tubes

- Titanium tubes

- Thermocouple tubes

- Subsea tubes

- Superheater tubes

- Stripper tubes

- Steam generator tubes

- Riser tubes

- Scrubber tubes

- Reheater tubes

- Recuperator tubes

- Production tubing (OCTG)

- Precision tubes

- Nuclear steam generator tubing

- Nuclear fuel tubes

- Muffle tubes

- Nitric acid tubes

- Medical tubes

- Mechanical tubing

- Laying head pipe

- ISO/EN tubes

- Lance tubes

- Hydraulic and instrumentation tubing

- High-temperature tubes

- High-pressure tubes

- Heat exchanger tubes

- GDI and CNG fuel system tubes

- Flowline piping

- Furnace tubes

- Flanges

- Fittings

- Evaporator tubes

- Finned tubes

- Downhole casing

- Ethylene furnace tubes

- Control lines

- Condenser tubes

- Coiled tubing

- Composite tubes

- Capillary tubes

- Chemical injection lines for demanding energy applications

- Boiler tubes

- ASME/ASTM welded pipe

- Bimetallic tubes

- ANSI/ASME pipe

- Aerospace tubes

-

High-performance materials

- Sanicro 35

- SAF™ 3006

- SAF™ 3007

- Sanicro® 35 Bridges the Gap Between Stainless Steels and Nickel Alloys for Chemical and Refinery Industries

- 1250°C heat protection for mineral insulated cables

- Titanium and zirconium

- Alleima® 2RE10

- Sanicro® 28

- Sanmac® stainless steels

- Alleima® 3R60: advancing the standards for corrosion resistance

- Clean H&I tubing for trouble-free systems

- Safurex®

- Alleima® 2RE69

- High-temperature stainless steels

- Duplex stainless steels

- List of alloys

-

Strip steel

-

Strip products

- Compressor valve steel

- Razor blade steel

- Doctor blade steel

-

Knife steel

- Kitchen knives

- Industrial applications

- Outdoor knife steel

- Damax™ damascus steel

- Size range

- Knife steel knowledge

- Material selection table

- Mechanical properties

- Our knife steels

-

Hardening guide

- Purpose of hardening and tempering

- The hardening procedure

-

Hardening programs

- Alleima® 7C27Mo2 piece hardening

- Alleima® 19C27 batch hardening deep freezing -70°C/-95°F

- Alleima® 19C27 piece hardening

- Alleima® 19C27 piece hardening deep freezing -70°C/95°F

- Alleima® 7C27Mo2 batch hardening

- Alleima® 14C28N piece hardening

- Alleima® 14C28N piece hardening deep freezing -20°C/-5°F

- Alleima® 14C28N piece hardening deep freezing -70°C/-95°F

- Alleima® 19C27 batch hardening

- Alleima® 14C28N batch hardening

- Alleima® 14C28N batch hardening deep freezing -20°C/-5°F

- Alleima® 14C28N batch hardening deep freezing -70°C/-95°F

- Alleima® 13C26 piece hardening deep freezing -70°C/-95°F

- Alleima® 12C27M piece hardening -20°C/-5°F

- Alleima® 13C26 batch hardening

- Alleima® 13C26 batch hardening deep freezing -70°C/-95°F

- Alleima® 13C26 piece hardening

- Alleima® 12C27 piece hardening deep freezing -70°C/-95°F

- Alleima® 12C27M batch hardening

- Alleima® 12C27M batch hardening deep freezing -20°C/-5°F

- Alleima® 12C27M piece hardening

- Alleima® 12C27 batch hardening deep freezing -20°C/-5°F

- Alleima® 12C27 batch hardening deep freezing -70°C/-95°F

- Alleima® 12C27 piece hardening

- Alleima® 12C27 piece hardening deep freezing -20°C/-5°F

- Alleima® 12C27 batch hardening

- Spring steel

- Shock absorber strip steel

- Coated Strip steel

- Thermocouple strip

- Resistance heating strip

- Medical strip steel

- Size tolerances

- Shape

- Edges

- Surfaces

- List of alloys

- Alloy surcharges

-

Strip products

- Plate and sheet

- Furnace products and heating systems

- Coated Strip Steel

- Billets and blooms

- Solid bar and hollow bar

- Alloy surcharges

-

Wire

-

Technical center

- Corrosion tables

- Corrosion knowledge

- Safety information sheets (SIS)

- Welding guide

- Shielding the weld

- Material datasheets

- Pressure calculations

-

Whitepapers

- Download whitepaper - Medical metals and coatings

- Download whitepaper - Sensors and remote monitoring

- Download whitepaper - A cut above

- Download whitepaper - Remote patient monitoring

- Download whitepaper - The benefits of electroplating for Medtech manufacturers

- Download whitepaper - The design potential of compressors through next-generation valve material

- Download whitepaper - Nitinol and its transformative role in medical devices

-

Webinars

- 肥料用途:耐腐食性材料の選定ウェビナー

- Captura, Utilização e Armazenamento de Carbono : Uma Introdução a Seleção de Materiais

- Carbon Capture, Utilization, and Storage: Introduction to Material Selection Webinar

- Carbon Capture, Utilization, and Storage: Introduction to Material Selection Webinar

- The Duplex Stainless Steel Webinar Series: Get the best of both worlds

- O&G Applcations: Technical Benefits of a Seamless Control Line for Downhole

- Corrosion Resistant Alloys for Heat Exchanger in the Chemical Process Industry(2)

- O&G Applications: Technical Benefits of a Seamless Control Line for Downhole Webinar 2

- Sanicro 35: Bridging the Gap Between Stainless and Nickel Alloys for Refinery Applications

- Corrosion Resistant Alloys for Heat Exchanger in the Chemical Process Industry

- キャリア

- Contact

- Investors

- News & media

- 会社概要

- Sustainability

-

Campaigns

- Introducing the next generation of super-duplex materials

-

900 ways to make a change

- Supercritical water gasification – a promising renewable technology

- Solar towers to power the future

- Supporting the expansion of hydrogen infrastructure

- Life-changing solutions with Alleima® medical wire

- Energy efficiency improvements with Freeflex™

- Sanergy™ LT brings fuel cells for the future

- Electric heat treatment for Ovako

- Electric heating reducing climate impact

- Hidden heroes of industry

- 言語の変更

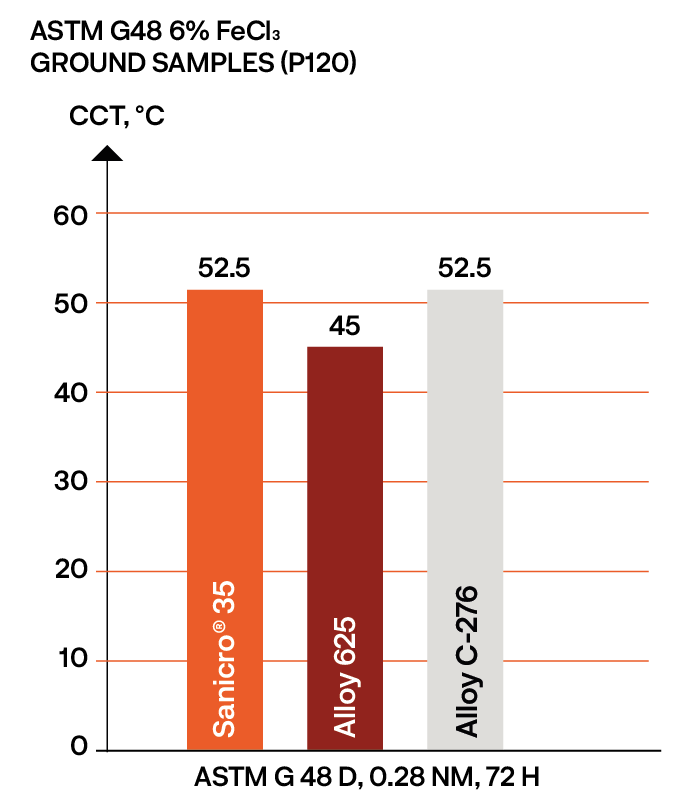

Sanicro® 35 has crevice corrosion resistance higher than Alloy 625 and at least on par with C-276.

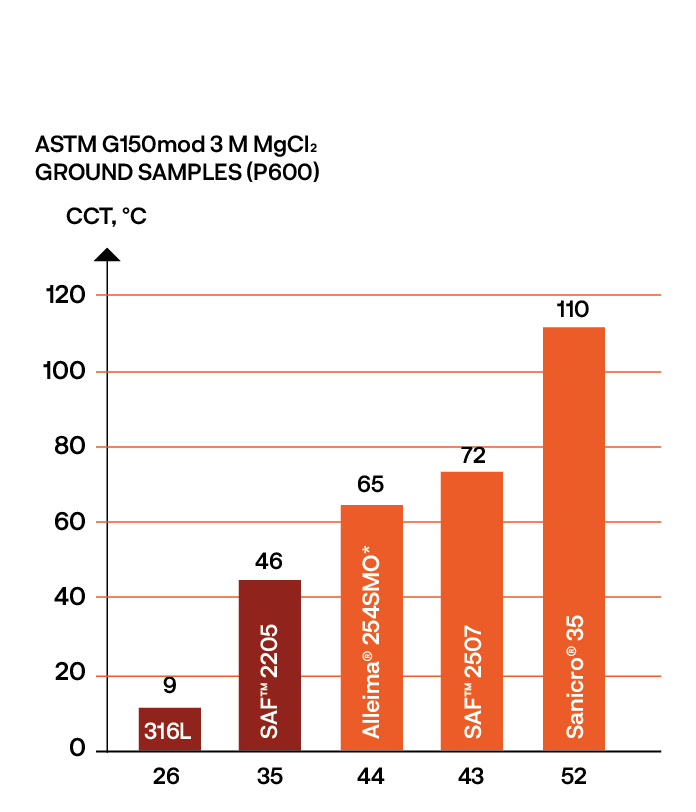

Sanicro® 35 has crevice corrosion resistance higher than Alloy 625 and at least on par with C-276. Sanicro® 35 is designed to handle a significantly higher critical pitting temperature than standard grades. Note: 254 SMO is a trademark owned by Outokumpu OY.

Sanicro® 35 is designed to handle a significantly higher critical pitting temperature than standard grades. Note: 254 SMO is a trademark owned by Outokumpu OY.